Abrasive Wheel Guards Should Follow Which of the Standards Below

Always handle abrasives wheels in careful manner. Its just for fun and tests your knowledge on construction health and safety here in the United Kingdom.

Dekton Dt80630 115 Mm Aluminium Oxide Flap Disc 40 Grit In 2022

The following interests are represented on Committee SF12.

. The maximum angular exposure of the grinding wheel periphery and sides shall be not more than 90 deg except that when work requires contact with the wheel below the horizontal plane of the. The following topics will be covered. Before you handle an abrasive wheel it should always undergo some basic inspections.

215a4 Is the work rest used and kept adjusted to within 18-inch 03175cm of the wheel. It must be adjusted so it is located between the operator and the cutting off wheel. Straight cutting off wheels such as Type 41 formerly denoted as Type 1 used on a portable angle grinder with a Type 27 28 raised hub or depressed center grinding wheel guard.

Below are examples of properly guarded angle grinders. Australian Electrical and Electronic Manufacturers Association. 215a2 Do side guards cover the spindle nut and flange and 75 of the wheel diameter.

The maximum angular exposure of the grinding wheel periphery and sides shall be not more than 90 degrees except that when work requires contact with the wheel below the horizontal plane of the spindle the angular exposure shall not exceed 125. Types and characteristics of abrasive wheels. The combined use of wheel guards eye protection and face shields can reduce the chance and severity of a face injury.

This answer has been confirmed as correct and helpful. Use of abrasive wheels. Why not take our Abrasive Wheels Quiz with 10 questions.

ANSI B71 has been called the Bible for grinding wheel safety for good reason. Is the maximum exposure angle on all grinding wheels 180º or less. The maximum aperture should not exceed 185.

215d1 Is the maximum RPM rating of each abrasive wheel compatible with the RPM rating of the grinder motor. Between the safety guard and the top periphery of the wheel must not be more than 14-inch. It was approved on behalf of the Council of the Standards Association of Australia on 10 December 1986 and published on 2 February 1987.

Abrasive wheel safety guards for bench stands floor stands and cylindrical grinders shall not expose the grinding wheel periphery for more than 65 degrees above the horizontal plane of the wheel spindle. If it doesnt then it may be cracked so slightly that you cant even see it. 29 CFR 1910243c3 and 4 and 1926303c5.

You should teach your employees to always perform the ring test by tapping the wheel at a 45-degree angle. Ii Mounted wheels used in portable operations 2 inches and smaller in diameter. The use of abrasive wheels in an unsafe way often causes accidents leading to personal injuries and damage to properties.

If this distance is greater because of the decreased size of the abrasive wheel then a tongue guard must. It is recommended that all personnel involved in the use handling and purchasing of abrasive wheels become familiar with below standards. Each question is multiple choice and has only one correct answer.

Cover the spindle end nut and flange projections Dont exceed the strength of the fastenings and Maintain proper alignment with the wheel. Floor stand and bench mounted abrasive wheels used for external grinding shall be provided with safety guards protection hoods. Your abrasive wheel guards should follow which of the standards below.

1926303 c 1 Floor stand and bench mounted abrasive wheels used for external grinding shall be provided with safety guards protection hoods. Your abrasive wheel guards should follow which of the standards below. From the Abrasive Wheel standard.

In case of straight and taper. The guard must be so designed as to allow it to be opened removed on one side. It should a metallic ring after tapping it.

And iii Types 16 17 18 18R and 19. Guards rests and accessories. After you have completed the quiz you will be shown your score.

The presence of an abrasive wheel safety guard is not enough. Some abrasive wheels may be equipped with flanges. Cover the spindle end nut and flange projections Dont exceed the strength of the fastenings and Maintain proper alignment with the wheel.

They must be so designed as to be between the operator and the grinding wheel. A General requirements - 1 Machine guarding. Handle Abrasive Wheels With Care.

This Australian standard was prepared by Committee SF12 Abrasive Wheel Safety. Be installed to protect workers from flying fragments in case of wheel breakage. Wearing a face-shield can offer the end user.

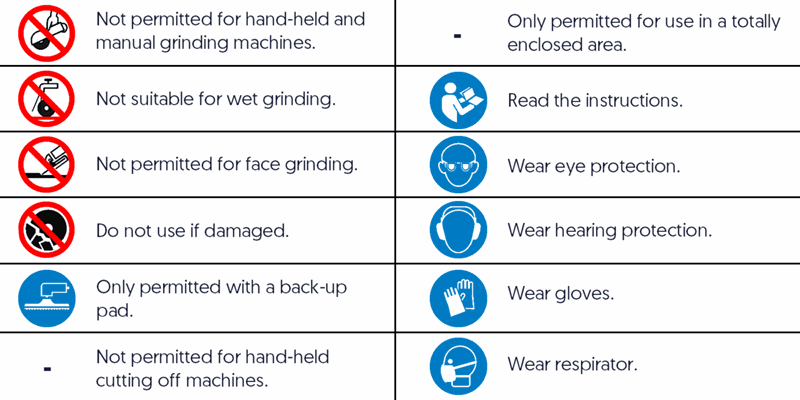

I Wheels used for internal work while within the work being ground. 1 the wheel guards with minimum exposure angle 2 the clearance between the work-rest and the wheel should be less than 32 mm 18 3 the protective screen or wear eye protectors Always report any fault or unusual signs of the machine to your foreman or supervisor. Cover the spindle end nut and flange projections Dont exceed the strength of the fastenings and Maintain proper alignment with the wheel.

215b9 Is the adjustable tongue guard on the top side of the grinder used and kept to within 14-inch 06350cm of the wheel. GUARDS FOR HAND HELD ANGLE AND FACE GRINDERS Guards for type 27 grinding wheels should have a maximum aperture of 185. 215b9 Is the adjustable tongue guard on the top side of the grinder used and kept to within 14-inch 06350cm of the wheel.

All of the answers. Cover the spindle end nut and flange projections Dont exceed the strength of the fastenings and Maintain proper alignment with the wheel. It is the abrasive grinding wheel industry standard for the Safety Requirements for the Use Care and Protection of Abrasive Wheels and most abrasive wheel safety-related questions can be.

Added 952020 111847 PM. Abrasive wheels shall be used only on machines provided with safety guards as defined in the following paragraphs of this section except. ALWAYS use the correct wheel guard.

The cup wheel hangs below the guard meant for a Type 27 or Type 28 wheel and in the event of a wheel breakage it offers little or no protection. Specific requirements concerning the safety guard are discussed below. Abrasive wheel machine parts.

Portable and Other Abrasive Wheels. Do all machines with abrasive wheels greater than 2 inches in diameter have safety guards. Your abrasive wheel guards should follow which of the standards below.

215a4 Is the work rest used and kept adjusted to within 18-inch 03175cm of the wheel. Type 27 28. Operating speeds for abrasive wheels.

Your abrasive wheel guards should follow which of the standards below.

1910 215 Abrasive Wheel Machinery Occupational Safety And Health Administration

Top 9 Faqs About Abrasive Wheels Commodious

1910 215 Abrasive Wheel Machinery Occupational Safety And Health Administration

Comments

Post a Comment